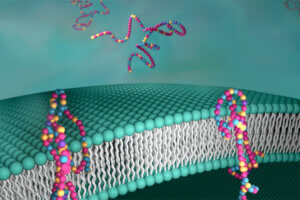

To separate liquids and gases according to density in centrifuge laboratories; It is used to settle bacteria, microorganisms, parasites, non-living particles to the bottom with the help of gravity. The force of gravity causes particles of higher density relative to the solvent to sink and particles of lower density to rise above the solution. The density differences required to separate particles in a solution can be very small. Centrifuges are often used in research and clinical laboratories for cell, organelle, virus, protein and nucleic acid purification.

Laboratory centrifuges are one of the most common laboratory equipment.

Laboratory centrifuges used in both research and clinical settings can be found in many laboratories. But they are perhaps most commonly used in chemistry, biochemistry and molecular biology laboratories. Some of its most common applications include separation, purification, and isolation of organelles, cells, and cell components, as well as more complex mixtures of nucleic acids, proteins, and viruses for further observation.

The first centrifuge was used to separate cream from milk.

Origins of the centrifuge 18. It dates back to a rotating arm apparatus designed by British military engineer Benjamin Robins in the 19th century to determine friction. In 1864 Antonin Prandtl applied this technique to separate milk and cream components. In 1875, Prandtl’s brother Alexander improved the technique by inventing a machine for extracting butter. While centrifuges are still used to separate milk components, their use has spread to many other fields of science and medicine.

Centrifuges did not progress and did not attract attention until advances in biochemistry led to a demand for highly centrifugal devices. With the advancement in medicine, the increasing demands (the need to separate cell components and later the increasing demand in virus research) led to several developments in centrifuge technology and eventually centrifuges became one of the most used equipment in laboratories today.

What does a centrifuge do?

Centrifuges separate heterogeneous mixtures into their various components. One of its most common uses is to separate red blood cells and other blood components from whole blood. The centrifuge works on the principle of sedimentation. Sedimentation refers to the tendency of suspended particles to settle out of the environment in which they are held and stand against a barrier. The centrifuge uses centrifugal acceleration to separate the particles from the solution.

Centrifuge does not rely on gravity, it creates centrifugal force.

If the density of the solution is higher than that of the solvent, the particles settle to the bottom of the tube. If the density of the solution is lower than that of the solvent, the particles will float to the top. The greater the density difference between the solution and the solvent, the faster the particles move. If the density between the two remains the same, the particles remain constant in solution. Where particles need to be separated from a solution where there is little or no density difference, the centrifuge creates a centrifugal force to separate the particles instead of relying on gravity to do the work.

What are the uses of the centrifuge?

1) Separating Molecules and Isotopes

Extremely high-speed centrifuges and ultracentrifuges spin at such high speeds that they can be used to separate molecules of different masses and even atomic isotopes. Isotope separation is used for scientific research and to make nuclear fuel and nuclear weapons. For example, a gas centrifuge can be used to enrich uranium because the heavier isotope is pulled out more than the lighter one.

2) Laboratory

Laboratory centrifuges also spin at high speeds. They can be large enough to stand in one place or small enough to stand on a counter. While many laboratory centrifuges have fixed angle rotors, swinging bucket rotors are also common. Uses include separating blood components, isolating DNA, and purifying chemical samples.

3) High Gravity Simulation

Large centrifuges can be used to simulate high gravity. Machines are the size of a room or building. Human centrifuges are used to train test pilots and conduct scientific research on gravity. Centrifuges can also be used as amusement park rides. Human centrifuges are designed to weigh up to 10 or 12 weights, while large-scale non-human machines can expose samples up to 20 times normal gravity. The same principle could one day be used to simulate gravity in space.

4) Industrial Centrifuges

Colloid components (such as milk cream and butter) are used in chemical preparation, to remove solids from drilling fluid, to dry materials, and in water purification to remove sludge. Some industrial centrifuges rely on precipitation for separation, while others separate the matter using a sieve or filter. Industrial centrifuges are used to pour metals and prepare chemicals.

5) Daily apps

Medium-sized centrifuges are widely used in daily life, mainly to quickly separate liquids from solids. Washing machines use centrifugation during the spin cycle to separate the water from the clothes. A similar device spins water in swimsuits. Salad spinners for washing and then turning dry lettuce and other greens are another example of a simple centrifuge.

How does centrifugation work?

A centrifuge uses a motor to spin liquid samples at high speed. The speed at which a centrifuge’s rotor moves is usually expressed as RCF, which stands for relative centrifugal force in units of gravity. However, many devices display speed in RPM or revolutions per minute. As the rotor rotates around a central axis, it creates a centrifugal force that acts to move the particles away from the axis of rotation. If the centrifugal force exceeds the buoyancy forces of the liquid medium and the friction force created by the particle, the particles will settle. Centrifugal force moves dense components out of the container, allowing solids to settle completely and quickly.

There are different types of centrifuges that vary in size, sample capacity and rotor type.

Rotor type plays an important role in deciding when it’s time to buy a centrifuge for your lab. This is because the rotor affects what kinds of applications you can do. Also, glass or plastic tubes that fit into rotor cavities are used in centrifuges. The size and type of sample tubes affect the samples that can be used in the unit.

For example, glass tubes can be used with most solvents, but they are generally more expensive. Plastic tubes can be just as durable if handled with care, but water is the preferred solvent. If you need to work with larger samples you will want to use centrifuge bottles rather than tubes.

Centrifugal Rotor Types

There are three very common rotor designs: fixed pitch, swinging bucket and continuous flow rotors. The fixed angle rotor is designed to hold the pipes in a fixed position at a fixed angle with respect to the vertical axis of rotation (up to approximately 45°). Centrifugation causes particles to settle along the side and bottom of the tube. The rocking bucket design allows tubes to swing from a vertical resting position to become parallel to the horizontal during centrifugation. As a result, sediment will form at the bottom of the tube.

Fixed angle rotors are ideal for pelletizing applications to remove particles from a suspension and discard debris or recover the pellet. Whereas, swinging bucket rotors are best for separating large volumes of samples at low velocities and resolving samples in ratio-region (density) gradients.

Continuous flow rotors create a zone of higher concentration, which has a greater density than the surrounding medium. There aren’t many applications that require specialized rotors such as continuous flow rotors or drum rotors compared to fixed pitch or swinging bucket rotors. But you see how important continuous flow is when needed.

Centrifuge Types and Uses

Small bench centrifuges: Also known as benchtop centrifuges, this type collects small amounts of material such as yeast cells and erythrocytes. Small bench centrifuges have a maximum relative centrifugal area of 3,000 to 7,000 times the force of gravity, known as the gravitational force or g-force (g). Compared to other options, these are relatively low speeds. These are a general purpose centrifuge and are among the most affordable options available today.

Large-capacity refrigerated centrifuges: Large-capacity refrigerated centrifuges have a cooled rotor chamber. It is possible to change the rotor chambers to fit another dimension. They pick up items that settle quickly, such as small bench models, and at a maximum speed of 6,500 g.

High-speed refrigerated centrifuges: High-speed centrifuges are very similar to large-capacity models, except that they can reach a maximum speed of about 60,000 g. These models can collect larger cellular debris, microorganisms, and proteins precipitated by ammonium sulfate. Refrigerated models may also have a cooled rotor chamber.

Ultra centrifuges: Ultra centrifuges are optimized to spin at very high speeds, which can reach 1,000,000 g (9,800 kilometers per second or 6,089 miles per second). Such centrifuges are classified as preparative or analytical.

Prep ultracentrifuges: Prep ultracentrifuges reach approx. 600,000 g. They are used to determine the shape and mass of macromolecules, to separate lipoprotein molecules from plasma, and for a variety of other tasks. Preparatory ultracentrifuges have refrigerated, sealed and evacuated chambers.

Analytical ultracentrifuges: With an analytical ultracentrifuge, three optical systems can be selected: Light absorption system, Schlieren system and Rayleigh interferometric system. The Schlieren and Rayleigh systems are used to detect changes in the refractive index of the solution, while a light absorption system detects the changes through ultraviolet light absorption. These models operate at approximately 500,000 g.

Four Basic Safety Precautions to Take When Working with a Centrifuge

1) Provide a firm, flat work surface. Always make sure the centrifuge is on a suitable surface before operating.

2) Balance the centrifuge. Operating an unstable centrifuge can cause significant damage and injure the operator and other laboratory personnel. The total mass of each tube should be as close as possible. This becomes increasingly important at very high rotor speeds. It is recommended to balance the masses to the nearest 0.1 gram and it is important to balance the tubes by mass, not volume. For example, do not balance a sample consisting of an equal volume of water with a liquid with a higher or lower density than water.

3) Do not open the cover while the rotor is in motion. Many centrifuges have a “safety shutdown”. However, this will only shut off power to the rotor and the rotor will continue to rotate due to its own inertia for a while until it stops due to friction.

4) If the centrifuge is shaking, unplug it. A little vibration is normal, but excessive amounts can mean danger. First, double check that the tubes are properly balanced. If this does not solve the problem, do not start the centrifuge until it has been serviced by the manufacturer or dealer.

How to balance a centrifuge? Why do you need to balance a centrifuge?

Before starting the centrifuge, it must be loaded correctly. Balancing the centrifuge prevents possible damage to the instrument and is essential for safe operation. Make sure all sample tubes are filled evenly. If additional tubes are required for equilibration, fill them with water or a liquid of similar density to the sample and ensure that the mass equilibrates to the nearest 0.1 gram. For each tube placed in the rotor, add an equal weight tube opposite it. This will ensure that the center of gravity remains at the center of the rotor. Rotate the rotor 90° and add two additional tubes directly opposite each other.

How to maintain a centrifuge?

A few simple steps can keep a centrifuge working properly and reduce the risk of damage and malfunction.

- Keep the centrifuge properly lubricated. O-rings are the main source of protection against sample leakage and should be lubricated before installing a new rotor or after cleaning. Threaded components should also be cleaned regularly and lubricated with an approved grease to ensure smooth operation and prevent cross threading and corrosion.

- The buckets must be properly seated on their pins, the tubing in the rotor must be balanced, the rotors must be operated within the specified guidelines for the specified speed and maximum bulkhead mass, and to avoid scratching the rotor. It should also be noted that all users are aware of how to operate the centrifuge properly.

- Inspect critical components and look for signs of wear, including scratches, or chemical effects on the rotor.

- Pay close attention to noise, vibration, shaking or squeaking and stop the unit immediately if this occurs.

Centrifuge Cleaning

Clean the centrifuge regularly with neutral cleaning solutions (alcohol or alcohol-based disinfectant) applied to the rotors and accessories with a soft cloth. Daily cleaning should include the inside of the centrifuge, the rotor chamber, and surfaces with electronic components such as touchscreens and keypads. It is important to be aware of the different types of samples used with the centrifuge and any specific products required to clean up spills.

7 Essential Questions to Ask When Buying a Centrifuge

1) What sample volumes do you work with? For processes with large or variable volumes, a floor-standing model with higher capacity and different rotor configurations may be the best solution.

2) What speed and g-force is required for your application? What is the maximum g-force the centrifuge can produce? Low speed centrifuges are ideal for separating whole cells, while ultracentrifuges are required to separate DNA and RNA.

3) How much laboratory space is available? Many different sizes of floor and countertop models are available.

4) Will you work with temperature sensitive samples? Is cooling and temperature control necessary? If so, a centrifuge with cooling and temperature control options is required.

5) What rotors are available and how easy are they to replace?

6) Does the unit have additional safety features such as mechanisms to prevent accessories from exceeding maximum speeds or unbalance detection?

7) Will the centrifuge be used for processing clinical or blood banking samples? Cell washers or clinical models are available for these specific applications.

Sustainable Centrifuges: Greener, Affordable, Cost-Effective and Enhanced Performance

As sustainable laboratory equipment becomes more commonplace in the life sciences, the idea that sustainability only comes at the expense of performance is changing. In fact, the opposite is often true. Sustainable solutions provide many additional benefits, such as increased efficiency, which often equates to lowering costs. Regarding centrifuge equipment, manufacturers work closely with laboratories to understand the requirements in terms of both performance and sustainability. This partnership has led to huge leaps in innovation in recent years.

Optimizing Centrifuges for Sustainability and Performance

Performance is at the heart of every innovation, and next-generation centrifuges combine advanced technology, innovative materials and smart design to deliver high performance as well as exceptional efficiency and energy savings, some of which are more than 70 percent.

Greener operation: This is perhaps the simplest of the sustainability features on the market, but one of the most effective. Energy-efficient operating modes automatically detect when a centrifuge is idle and put it into sleep mode. This feature significantly reduces energy use, with some models seeing a reduction of over 60 percent.

Innovative rotor design: As the main moving part of the centrifuge, the rotor has the greatest energy requirement. At speeds up to 30,000 RPM on some super-fast models, friction can increase energy demand. New generation centrifuges with wind shielded rotors provide a more efficient airflow and reduce energy requirements. Innovative rotor materials are also more energy efficient.

Carbon fiber rotors are lighter than their aluminum or titanium counterparts, providing faster acceleration and deceleration rates and shorter run times for cost and time savings. Carbon fiber also has a longer lifespan than metal, as it is more resistant to damage by chemicals, which increases uptime and reduces waste. Combined with the fact that many carbon fiber rotors are repairable, thus increasing their lifespan, the sustainability benefits are even greater.

Minimal friction: Due to centrifugal rotors rotating at such high speeds, they are particularly susceptible to energy inefficiencies caused by friction. Some centrifuges now have vacuum features that remove up to 80 percent of the air surrounding the rotors and significantly reduce the amount of energy required to rotate samples and power the centrifuge. For maximum effectiveness, the vacuum should be adjusted according to the rotor and speed settings, as well as to meet the requirements of super speed programs.

Automatic door opening with efficient cooling systems: Centrifuges are carefully controlled to maintain optimum temperatures that protect samples and centrifuge technology. This energy is wasted when the doors are opened and the cooling systems continue to operate. Some centrifuges now offer cooling system auto shut-off features to prevent energy loss when the door is open, as well as more efficient cooling systems that further increase sustainability and cost savings.

Increased capacity: When the above sustainability features are combined with larger centrifuge capacity, even greater efficiencies in terms of time, cost and energy can be realized. Larger capacity units can run more samples in a single cycle and fewer cycles need to be completed. In busy laboratories where hundreds of samples can be processed per day, fewer cycles in a short time makes a huge difference in operating costs.

In any case, centrifuge innovation is focused on providing higher performance. But with added sustainability benefits, these innovations have resulted in increased efficiency, reduced waste and lower costs. Sustainability really benefits performance, and the two can work synergistically for reinforced rewards.

Sustainable Centrifuges: One Step On The Journey To Reduce Carbon Footprint

The next generation of centrifuges on the market today are already having a major impact on the industry’s carbon footprint, with some models reducing energy consumption by over 70 percent compared to conventional models. Saving 2,000 kilowatt-hours over the course of a year represents the equivalent of about 1.5 metric tons of carbon dioxide, and this is easily achieved with just one or two of the green features found on many next-gen models. This also means significant cost savings.

Today’s sustainable centrifuges are certainly becoming one of the pioneers of the future in the industry as equipment manufacturers are increasingly turning to sustainable designs wherever possible. More equipment is being designed with future repair and reuse in mind rather than replacing it. This includes refurbishment, in which working parts of end-of-life tools are repurposed. Such parts can then be reused in future models, ultimately reducing the need for raw materials.

Centrifuge manufacturers also closely examine their own carbon footprints. Some organizations now operate in zero-waste factories or seek to introduce new products with a net-zero environmental footprint. Of course, sustainability is not new to many equipment manufacturers. This sustainability journey continues, and thanks to many other new developments, laboratories aim to achieve their own sustainability goals by making sure that the equipment delivers levels of sustainability, energy efficiency and greenhouse gas reduction.

Sustainable centrifuges: The pursuit of continuous performance, efficiency and sustainability

Changes at the global and regional levels have made sustainability an important part of the global supply chain, thanks to the commitment of businesses and individuals to do their part to mitigate the impact of climate change. This movement is growing and will become a focal point for every business. Collaboration with internal departments and partnerships with trusted equipment suppliers will be key as organizations move to fully embrace sustainability as a performance indicator. Innovation will continue to drive performance further, but must also grow its impact through sustainable deliverables.

Few centrifuges offer stand-alone sustainable features, but next-generation, sustainable models take this a step further by combining the best of innovations to deliver massive energy savings, waste reduction and reduced greenhouse gas emissions.

Environmental features are now more closely linked to performance and business benefits. This means efficiencies are realized, costs are reduced, operational efficiency is improved and waste streams and associated costs are minimized. Laboratories can now not only meet their sustainable goals, but improve their services at a lower cost per sample; a win-win situation for all stakeholders.